Imagine clean, fresh water, an essential resource for life, flowing freely with every turn of a faucet. For many of us, this is something we take for granted. But have you ever stopped to wonder where this water comes from? For a significant number of people, it comes from a well system, a marvel of engineering that taps into nature’s own reservoirs beneath the ground. Today, we’re going to look below the surface into the fascinating world of well water, exploring “how does a water well work.”

Key Takeaways

-

Understand the basics of how a water well works and its components.

-

Ensure safe drinking water with filtration, treatment, testing and maintenance.

-

Compare city vs well water to choose the right system for your needs.

Understanding Well Water Sources

Well water is a naturally sourced groundwater, typically accessed by drilling into aquifers beneath the earth's surface. This type of natural reservoir acts like an ‘underground lake’, containing water that has been processed through many geological layers. These layers act as natural filters, purifying the water over time as it seeps deeper into the ground. The aquifers are often replenished by rainwater and other sources of surface water, ensuring a consistent supply. The process of accessing this water involves the use of a well, a man-made hole drilled deep into the ground. The depth of the well and the quality of the aquifer it taps into can significantly influence the quality and taste of the well water. Once accessed, this water can be pumped up to the surface for use in households and businesses.

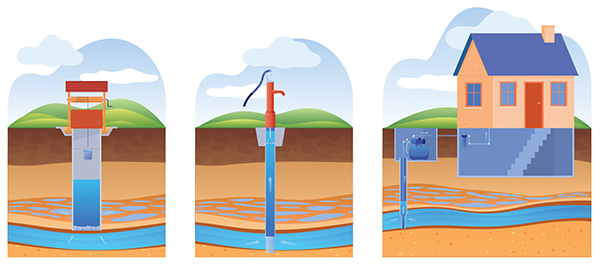

Types of Wells: Drilled, Dug, and Driven

To understand how we access well water, it is important to know the three main types: drilled wells, dug wells and driven wells. Each has its own benefits and drawbacks when considering water quality and contamination potential. Assessing each type’s characteristics along with their construction methods can help determine which one best fits our needs.

Drilled Wells

Drilled wells are the most prevalent type of water wells, created by employing rotary drilling machines to bore into the earth's crust. The equipment used in this process comprises a steel drill with an attached bit, connected to specialized vehicles. A drilling fluid or mud is used to lubricate and cool the drill, remove cutting, and maintain hydrostatic pressure, keeping the bore-hole open. These drilled wells typically reach depths between 100-200 feet in order to tap into dependable water sources and prevent contamination from surface water.

Dug Wells

Dug wells are shallow wells constructed manually by excavating a large hole in the ground, usually by hand. Typically, they reach no more than several meters below the water table, and have to be lined with stones or bricks for support the walls against potential collapse. One fascinating example of a dug well is the Big Well in Kansas, USA, which is considered the largest hand-dug well in the country. Unlike drilled wells which reach greater depths, dug wells are closer to the surface. This proximity to the surface makes them susceptible to pollution. Users of these shallower alternatives must take into account safety precautions as recommended by the National Ground Water Association.

Driven Wells

Driven wells are a practical method for acquiring water from shallow, sandy sources. The construction of these wells involves driving point-tipped, steel pipes into the ground. These can reach up to 50 feet if machine-driven or 30 feet if done manually. Since these wells are usually close to the surface, like a dug well, they have a greater risk of contamination from surface pollutants. Despite this potential problem, driven wells are a beneficial option for accessing groundwater in regions where the water table is high.

Key Components of a Drilled Water Well System

A well is not simply a hole in the ground, rather it is composed of multiple parts that work together for water extraction and delivery. Each part plays important role in keeping the system operating dependably.

Let's drill deeper into these components to better understand how they interact and support each other within the system.

Bore-hole

The bore-hole is a crucial component in the water well. It's essentially the hole that is drilled into the ground, reaching down to the aquifer. The bore-hole's depth and diameter can vary based on the type of well and the geological conditions. The depth is particularly important as it determines the quality of water that will be accessed. Deeper bore-holes are likely to reach cleaner, purer water, as it has been naturally filtered by the layers of earth. Thus, the bore-hole serves as the foundation of the entire system, allowing us to tap into nature's underground water reservoirs.

Well Casing

The well casing, generally constructed from materials like plastic, carbon steel, or stainless steel, acts as the structural backbone of a water well. Its robust design is built to withstand the pressure of the earth, safeguarding the well water against contaminants from surface water or runoff.

An integral part of this casing is the well screen. The well screen is a filtering device installed at the bottom of the well casing, allowing water to move from the surrounding earth into the well while keeping out unwanted sand and sediment. These screens are typically made of stainless steel or PVC, with slots carefully sized to coordinate with the surrounding geology.

Well Cap

The well cap serves as a protective layer, covering the top of the well casing to keep pollutants out. It also acts as a conduit for electrical wires that power the submersible pump and provides an entry point for carrying out repairs and maintenance tasks.

Pumping Unit

The pumping unit is an essential component of the well system that serves to pump water from beneath the surface into a pressure tank and the plumbing network. Available in different types, such as jet pumps and submersible pumps, these devices all have their own advantages for depending on the application.

A submersible pump can be situated within its casing underground, requiring no priming prior to use. When needed it uses an impeller to push water through a pipe to the surface. Jet pumps, conversely, are typically utilized in wells that don't exceed a depth of 26 feet. They leverage a principle known as the Venturi effect in physics. A comprehensive explanation of the Venturi effect can be found on SimScale's website.

Pressure Tank

The pressure tank, an integral part of a well system, serves as a storage unit for water. It plays a critical role in maintaining consistent water pressure, essential for the smooth operation of household appliances and fixtures. When water is pumped from the well into the pressure tank, it compresses the air in the tank until it reaches a preset level. As a faucet is turned on, the pressure in the tank propels the water into the plumbing system.

Pressure tanks come in various sizes, and the choice of size depends largely on the output of the well pump. Regular inspections and maintenance of the pressure tank can prevent issues like waterlogging, which can lead to premature pump failure. The pressure tank is a crucial component that ensures water is readily available when needed and at a consistent pressure.

Ensuring Safe Drinking Water: Filtration and Treatment

The aquifer’s natural filtration process is a good start towards ensuring the safety of well water, yet more purification may be needed. For this purpose, there are various types of systems that can target specific contaminants or issues – such as reverse osmosis for municipal and pre-cleaned well waters, whole house filters to ensure clean bathing water, and UV disinfection systems intended for surface and underground supplies. It must also be noted that regular testing should still take place in order to guarantee the performance effectiveness of these filtration methods so no impurities remain.

Well Maintenance and Testing Responsibilities

As a well owner, it is important to ensure the quality of your water by taking good care of your well and conducting tests on your tap. The CDC recommends examining the level of nitrates and bacteria in drinking water annually. They also suggest occasionally looking into any contaminants that may be present due to local conditions. You can have samples taken at an approved testing lab or purchase a home test kit for convenience. By conducting regular checks, you can identify and rectify potential issues before they escalate and potentially impact your health!

Comparing Well Water to City Water

City water and well water both provide clean, safe drinking water for households, but differ in some important ways. City water is filtered with chlorine or chloramine to remove bacteria, viruses and other impurities, and often have fluoride added to promote dental health. Well water is additive free, which may be beneficial for health, especially in sensitive individuals. City water systems undergo regular monitoring and testing required by health or environmental quality department rules and regulations, while private well testing is the responsibility of the well owner. Using a city’s municipal services often includes monthly usage costs, while private wells costs are minimal beyond beyond setup and maintenance.

Troubleshooting Common Well Water Problems

Maintaining your well system and ensuring it provides clean, safe, and reliable water involves regular inspection and testing. Here are some common issues associated with well water and how to troubleshoot them:

-

Hard-Water or High Fluoride Levels: These issues can be addressed by installing a water softening system or a specialized filter for fluoride. Regular testing will help monitor these levels and ensure they're within safe limits.

-

Turbidity: This is often caused by high sediment levels in the water. A sediment filter can help clear up the water by trapping these particles.

-

Fecal Bacteria: Contamination of well water with fecal bacteria is a serious issue. Regular testing is crucial for early detection. If detected, the well and water system should be thoroughly disinfected.

-

Oxidized Metals: High levels of oxidized metals like iron and manganese can indicate a high sediment level. A water treatment system designed to remove these metals may be necessary.

-

Unpleasant Odors: These can occur if there is a buildup of sulfur-producing bacteria in the well. This issue might be due to inadequate installation or certain types of heaters that lead to oxygen deprivation within deep wells. A well professional can help determine the cause and suggest the best treatment method.

You can find other water well terms in our glossary.

Remember, regular inspections and constant monitoring are crucial for maintaining the safety and efficiency of your well system. By staying on top of these check-ups, you can ensure the continued quality and reliability of your water supply. This is particularly important for a basic necessity like water. Regular maintenance and care of your well system can lead to long-term success and satisfaction, safeguarding the health and well-being of all users.

Choosing the Right Well System for Your Needs

When selecting the perfect well system for your property, it’s critical to take all aspects into consideration. The location of the building, as well as water source depth and quality, must be analyzed along with projected usage levels when deciding on a budget for a new installation. Professional advice from skilled contractors is highly recommended so that they can ensure optimal operation of the unit in order to preserve high-quality standards of the supplied water supply and increase home value at once.

Summary

It's quite fascinating to delve into the intricate world of well water - from its source, the various kinds of wells, the essential components of a well system, and the crucial role of filtration, treatment, and maintenance. By exploring this subject, we gain valuable insights into this vital resource that flows into our homes. Every drop is precious and gaining more knowledge about it is a key step in maintaining its quality and safety.

Frequently Asked Questions

How does a well refill with water?

Aquifers that supply water wells are primarily replenished through a natural process known as recharge. This occurs when rainwater or snowmelt percolates down through soil and rock layers into the aquifer. In some cases, water from lakes, rivers, and reservoirs can also seep into the ground and contribute to the recharge. The rate and extent of this recharge can significantly vary and depend on factors such as the permeability of the ground, the amount of rainfall, and the overall climate of the area. It's a delicate balance of nature that ensures a consistent supply of groundwater for wells, provided that the rate of extraction does not exceed the rate of recharge.

Does a well run out of water?

While water wells are typically designed to provide a consistent supply, there can be instances when they might run out of water. This can occur due to a variety of reasons such as prolonged periods of drought, overuse, or a drop in the water table. In such cases, the well may need to be deepened or a new one might need to be drilled to reach a more reliable aquifer. It's important to monitor water levels and usage to prevent a well from running dry and to ensure a sustainable water supply.

How does well water work for a house?

The modern water well system comprises a pump that draws water from the underground well, a pressure tank that maintains the water pressure, and a network of pipes that distribute the water throughout the house.

How deep should a well be for drinking water?

It is advisable to have a well that goes at least 100 feet deep when obtaining drinking water in order to avert any impurities from the surface. Most residential wells go between 100 and 800 feet below ground level for safety reasons. It is recommended that the well pump should be 10 to 20 feet above the bottom of the well. Check out our water well map to see the depths of wells in your area.

What are the disadvantages of well water?

Well water can be a challenge to maintain due to hard water and scale build-up, as well as being prone to containing hazardous contaminants like bacteria, lead and arsenic. Pumps used for such wells must typically be changed roughly every 10 years too.